Veldman overallconcept

construction, interior and sustainable energy

Since 1987 trading in

building materials and PVC

Sustainable energy

solar energy and more

A total sytem approach is required for the success of cage-free egg production. That is why Chore-Time offers a full line of feeding, drinking and egg collection systems with proven designs that lead the industry in performance.

Ultraflo Feeders

Ultraflo Feeders feature a fast delivery speed. Unlike other trough-style feeders, this means birds do not eat until the feeder stops, helping to ensure that each bird gets a uniform ration of feed.

Genesis Feeders

Genesis Feeders with special anti-roost devices are an ideal solution for feeding floor-raised layers. This innovative double-pan system allows producers to feed more birds in less space with uniform feed delivery and less feed waste.

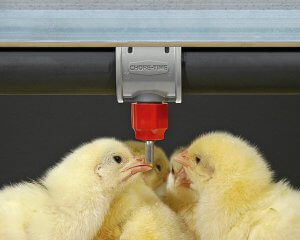

Nipple Drinking Systems

Chore-Time’s Relia-flow and Steadi-flow Nipple Drinkers feature a water metering system with all stainless steel or stainless steel on plastic parts in the flow control area for long-term delivery of the intended flow rate.

Bell drinkers

The water control panel ensures the water supply, which is guided via the closed circuit of Thylene hoses through the stable. The Sowa bell drinker is supplied with water through the closed circuit by means of a coupling and a PVC tube. The Sowa drinker has a waterflow regulating valve, allowing the user to adjust the water flow to desired level. The height of the Sowa bell drinkers can be adjusted by means of a height-adjuster or by means of a central winching system.

Water control panels

Water control panels include the following components:

Options:

Via a main pressure reduce valve (with combined or separate filter) the water is reduced to a pressure of around 1,5 – 2 bar. The water with reduced pressure is led through a watermeter, from which the water consumption can be read. After this the water can be led through a medicator. The medicator injects the desired liquid into the water. The tube is subsuquently drained and, depending on the type of drinking system, led to the drinking line. There are several sizes available, in ¾”or 1” execution. Water control panels are assembled when supplied, because of which they can be put to use instantly. Water control panels can be extended with an electrical valve to close off the water supply. Because of this it is possible to control the drinking times of the animals.

Water consumption can be read by means of a pulse emitter. The pulse emitter can be connected to the stable computer, which registers the water consumption. This makes the water consumption easy to manage.

Volito Egg Collectors

Volito Egg Collectors feature reliable motorized drive units, which each handle one 19.6-inch or two 9.8-inch egg belts. The drive can be equipped with a conveyor unit(not pictured) to transport eggs to the needed height. An egg elevator (pictured) is also available to transport eggs from different heights at the same time. Various combinations of these components contribute to maximum flexibilty for a variety of system configurations.